Wooden Pulley Wheel: Take 2This one’s for my sis…who seems to think I never fail at anything. It’s not true, I fail all the time. No biggie, I just keep looking for the one way that actually works for me. Yesterday I failed at making pulley wheels for my bathroom cabinet door…..tomorrow I have a few more ways to try ;0)

In the back of my mind I always did plan on using wooden wheels for my cabinet door. What I kept telling my husband was I needed to get the hardware store to look for metal ones….that kept getting put off for trips to town for stuff like groceries and gymnastics lessons rather than walking up and down hardware store aisles with kids in tow.

Since I didn’t have metal ones yet, I decided I had figured out how to make wooden pulley wheels. How hard can it be right? They’ve been using pulleys for centuries. Remember Archimedes? That crazy greek who ran naked through the streets yelling Eureka? Yip, they’ve been around since him.

Plan A

I was so sure that Plan A was going to work that I took tons of pictures to show you how genius I am. Not. As it turns out this time ;0)

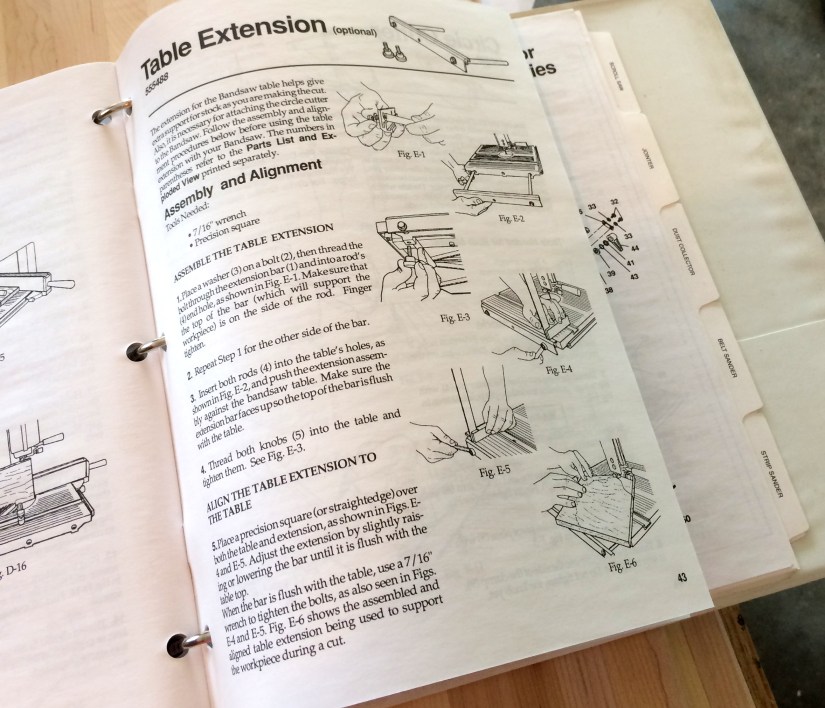

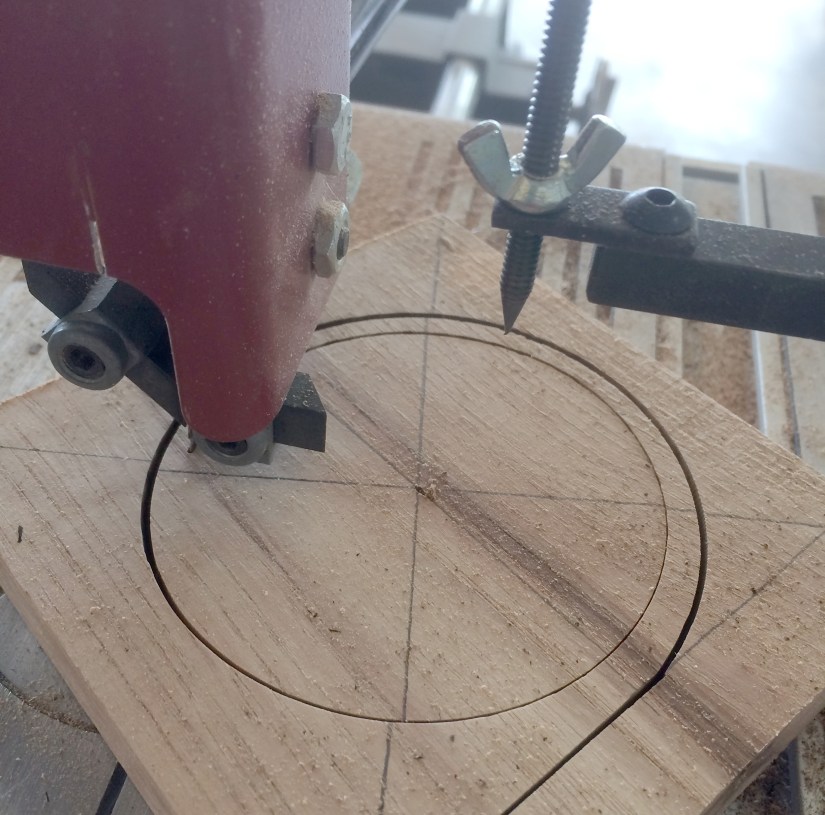

This plan involved using the cir cutting jig I bought off eBay for my Shopsmith bandsaw. I had it neatly stowed away in a drawer, pulled it out and had no idea what I was looking at. So out came the owner’s manual. It wasn’t nearly as intimidating as all the little pictures made it look like might be at first. I think this story is best told in pictures….

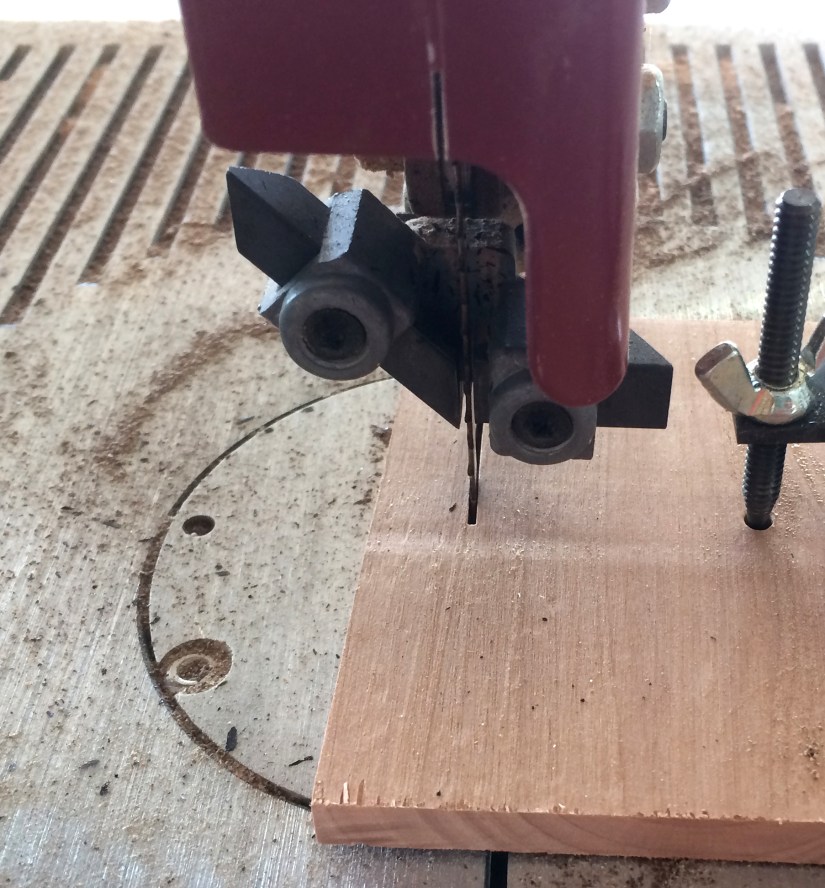

Jig assembled!! Not to whip out a couple of circles with a few spares to be safe. Piece of cake, I would be done in a jiffy. Better document this though, so I could share with you my triumph!!

It’s time to fess up to the real problem….my blade was so dull all the hardwoods were smoking!!! Then I remembered the last thing I cut with it….really dirty old beams for my daughters Herringbone End Grain Floor…..this explains a lot. I didn’t have a narrow enough spare, so why not try to sharpen it. What have I got to lose…besides a half hour.

About this time, my husband walked into the garage, looked at what I was doing and said, “why don’t you use a hole saw on the drill press?”

Um, oh yeah, I do have a large one of those, exactly the size I was trying to cut all of these circles for the last hour and a half……

Plan B

Plan B had it’s share of hiccups as well….but overall went a whole lot smoother.

The hole saw set-up didn’t work out. As soon as the saw got near the wood, it started to spin. Lucky we were able to find a different adapter and put a longer drill bit in it. It would still spin on occasion as I touched the saw to the wood, but I could tighten it up and carry on.

Finishing touches

Pulley wheels have a groove along their edge for the rope or belt to slide along, I had a genius idea to get one there. I would use the router table and spin the circle over a cove bit, raising it a little at a time until it was deep enough. It almost worked….actually it did work on my practice wheel….then not quite on a possible real wheel.

And realized that something was significantly off center….and you probably don’t want a pulley wheel with a wavy groove.

There you have it….how to spend that afternoon and not get one single pulley wheel. I could have probably monkeyed with the router table jig and gotten it to work reasonably well, but I needed to clean up and clear off because Clint was coming over to help me glue-up the arch for my dad’s fireplace as we use the router table for that. Picture of fireplace plan here.

Sucessful pulley wheels: Wooden Pulley Wheel: Take 2

Don’t forget to hit the follow button, or like my page on Facebook “Girl with a Hand Plane” for more projects and tips!

1 thought on “How NOT to make a Wooden Pulley Wheel”