At first I thought I needed to hurry up and get the extensions put on my bandsaw mill so I could mill longer logs…but it turns out that our little tractor won’t pick up anything longer than an 8’ oak log, so I’ve cut the ends off of the longer logs in order to mill them.

Having different lengths of logs can become a challenge when you go to make your stack, especially when you end up with more short pieces than you can easily disperse between the long ones.

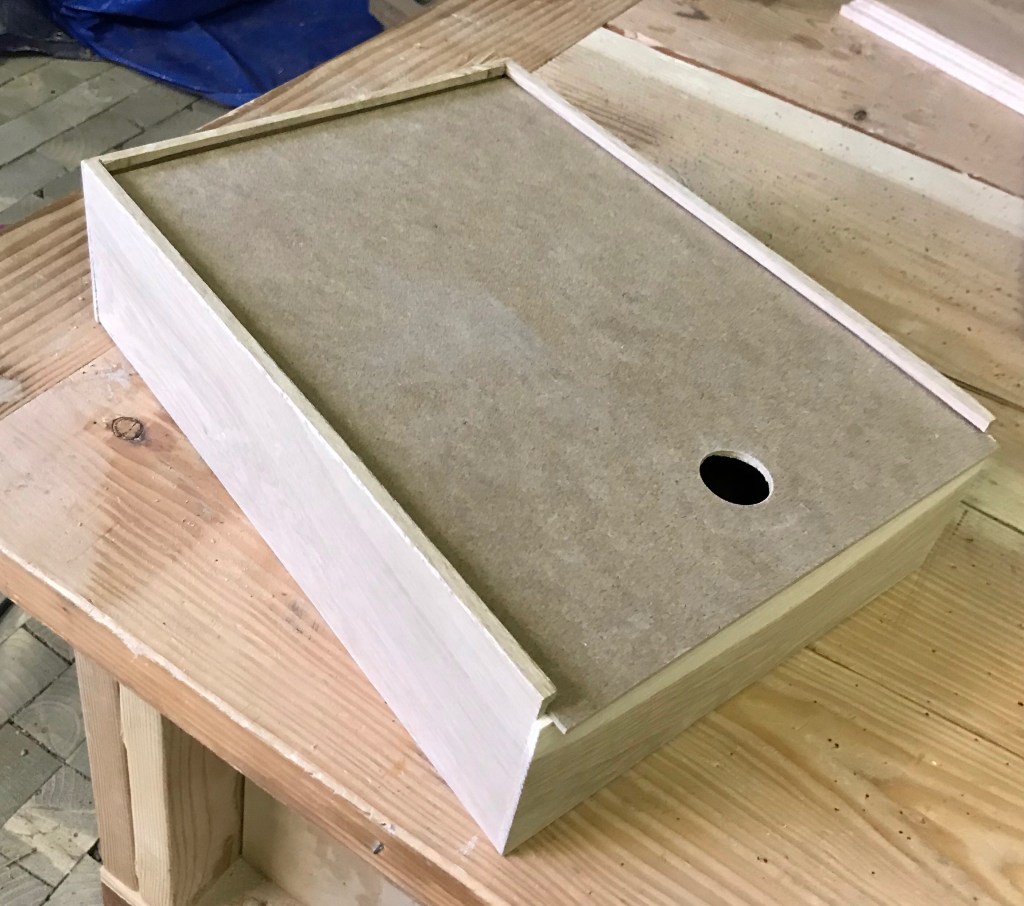

Holes like the one pictured can warp the boards above them as they dry. The top boards on this stack are my first milling mistakes, so I’ll be lucky to get much usable lumber out of them. They are heavy! And help hold down the rest of the stack!

I’ve been making some boxes for my mom’s quilt shop using 1/4” stock, but there is a lot of waste when you start with a 1” board and resaw it with the table saw, then plane each split side down to 1/4”.

Rather than try to add my last 4’ long to my drying stack, I decided to mill it really thin and dry it in the shop as an experiment. Here goes nothing!

I milled this log section first yesterday…but didn’t get to stacking it until after supper. I’m hoping the tannin stains don’t run too deep from it staying wet all afternoon between the boards. I was worried that if I spread them out to dry they would start cupping and warping on me before I could get them stacked. I ended up with 16 half inch boards from that 4’ section of log.

In the shop the first thing I did was cut a pile of 1/2” stickers 9-1/2” long, then cut some 4×4’s down to 10” to start the stack on. After picking a spot on the floor close to the wood rack, I laid out my base using a 2×4 to line everything up.

Then I brushed and scraped the wet sawdust off both sides of each board and started stacking. I’m pretty sure I had too much water on the blade for this log, there was a lot of sludge stuck to some of the boards.

Once I had them all stacked, I looked around for something heavy enough to weigh them down. Dunnage wood seemed like a good option, so I picked a couple of rough looking oak 4×4’s from off the rack and cut them to 4’ lengths and stacked them on top.

Hopefully all this means that I can use some of the beautiful grain in future small box projects! So, it was really hard to get a decent picture of the grain with only the overhead lights in the shop on and no daylight to work with. Check out those ray flecks!

You end up with quite a few more pretty boards by sawing it this way…now to see how they dry!

Don’t forget to hit the follow button, or like my page on Facebook “Girl with a Hand Plane” for more projects and tips!